Maximize yields

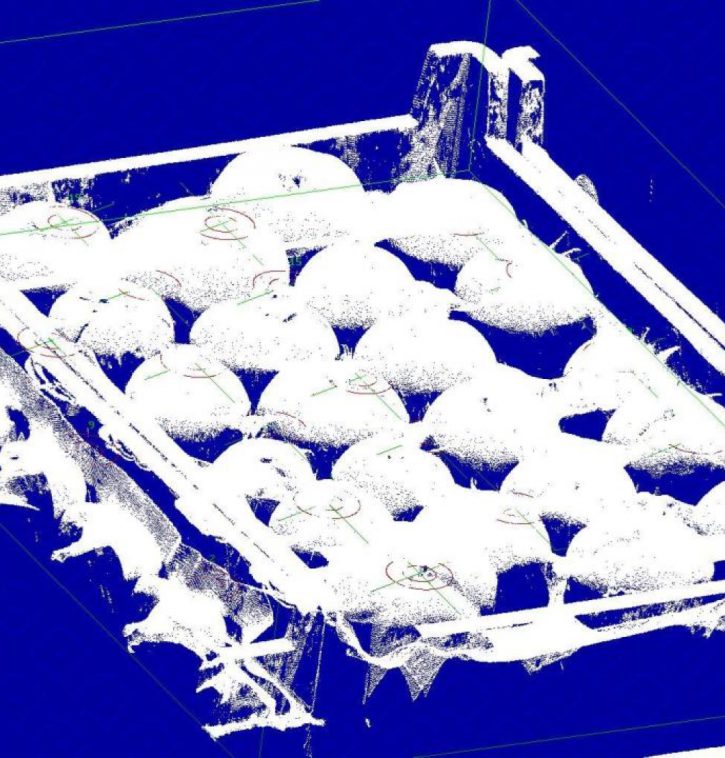

The combination of robotic or mechatronic handling with computer vision and AI can operate 24/7/365 enabling higher productivities with less resources or even without humans workers. As the systems optimize what product to handle when for designated purpose (package or other activity) yields will increase and waste will be minimized. The result is optimized revenues per square meter. Ultimately the system predicts the yields of tomorrow so sales can be done in advance at the highest possible level.

Reduce waste

The crop friendly handling and gripper systems ensure that products are less damaged and hence produce gets wasted. Computer Vision combined with AI ensure optimal grading and handling ensuring the ideal packed product ends up in designated package types with minimal give-away in size or weight.

Increase Food Safety

These automation systems result in less humans in the greenhouse or packing hall reducing the probability of virus spread and use of pesticides. Data and images from sensors and cameras are recorded for full track and trace-ability of intermediate steps from greenhouse row to packed product. Data is available per product, batch, customer real-time and afterwards and can be shared across value chains.

Differentiate on quality

Computer Vision combined with AI and mechatronic handling ensure that only the right class product is processed and in such a way that the final (packed) product is of uniform quality and according to customer recipe or specification. Producers can change settings in simple user interface in order to differentiate where applicable.

Reduce human dependency

Labor cost is the #1 cost driver within greenhouse horticulture and fresh produce. Availability of (good) labor is becoming scarcer and people can spread viruses and are at the end inconsistent in handling of organic products. These automation technologies enable to conduct the work with less or no people with higher scalability.

Extend shelf life

Mechatronic handling systems for internal transport and product specific robot grippers handle the plant, fruit or vegetable in an optimal way, taking into accunt its characteristics and grade. These systems will lead to less damages, more hygienic handling (versus humans) and processing in an optimal way (related to size, class versus package type). This crop friendly handling will result in extended quality and shelf lives.